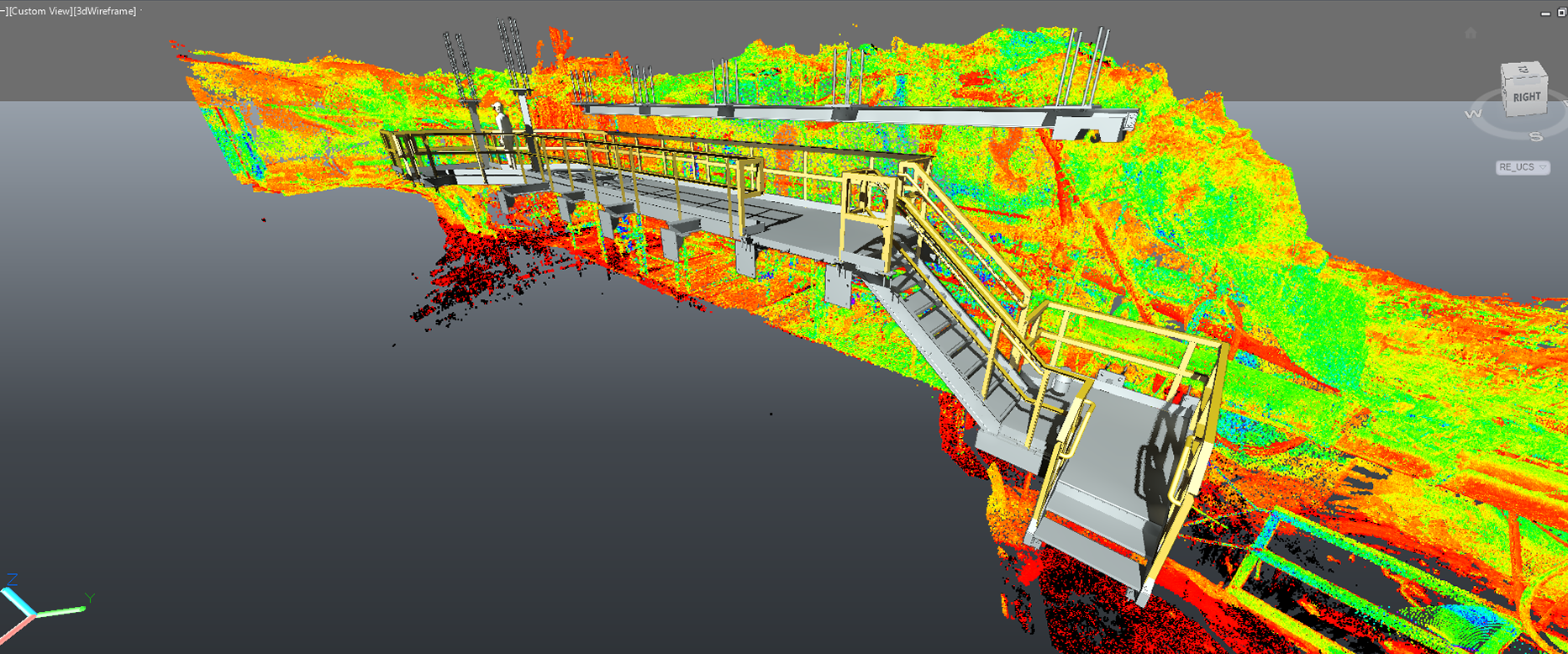

An operating mine had a timber platform accessing an existing sump that required replacement. The replacement platform was to be of structural steel construction. The replacement steel had to fit to the existing complex drift profile.

In addition to the platform, a monorail to move pumps to and from the sump had to be included in the design.

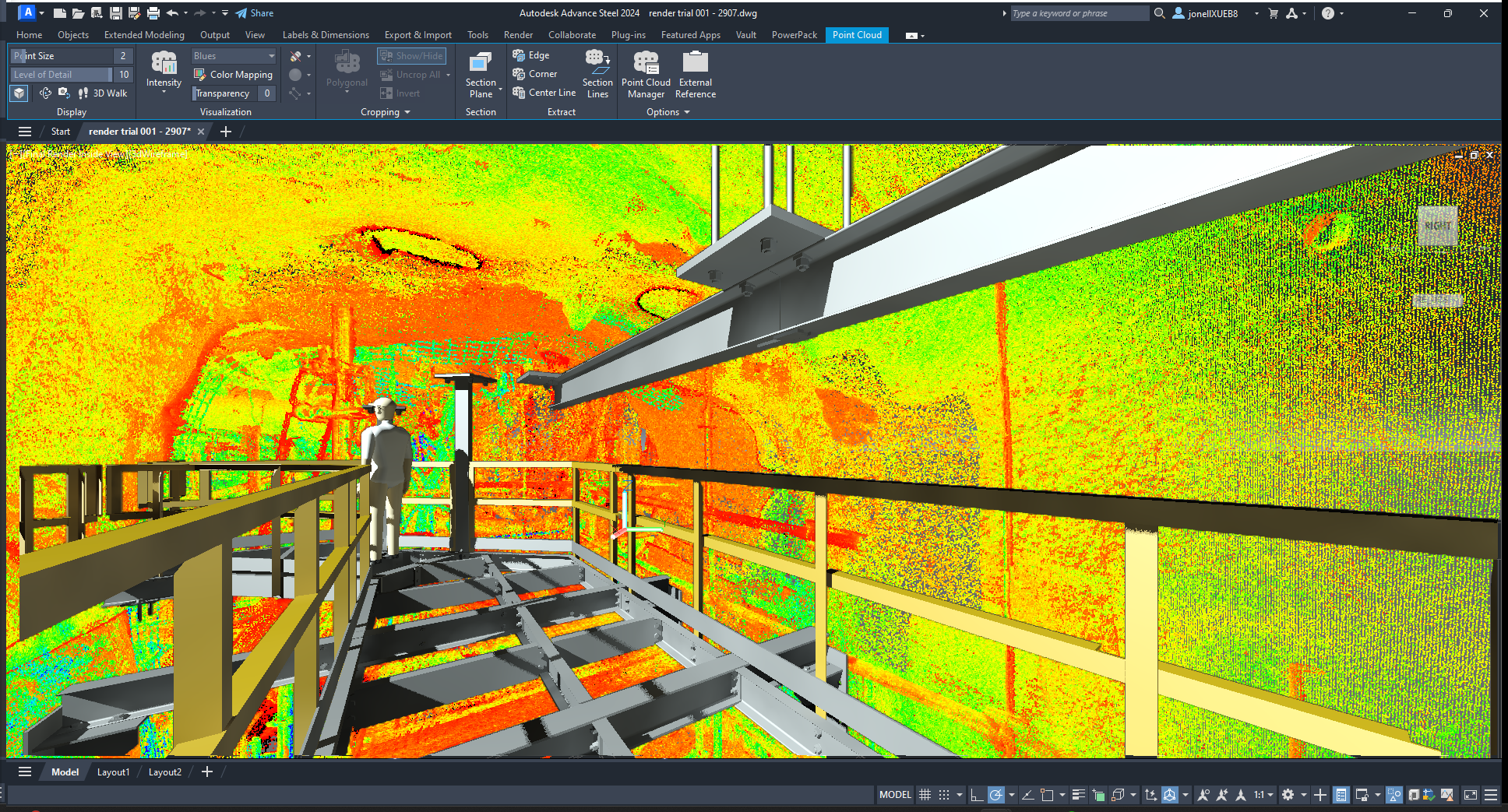

A laser scan of the existing drift was performed. A 3D model using the resulting point cloud was created to ensure the platform fit in the existing drift and would easily install without interferences.

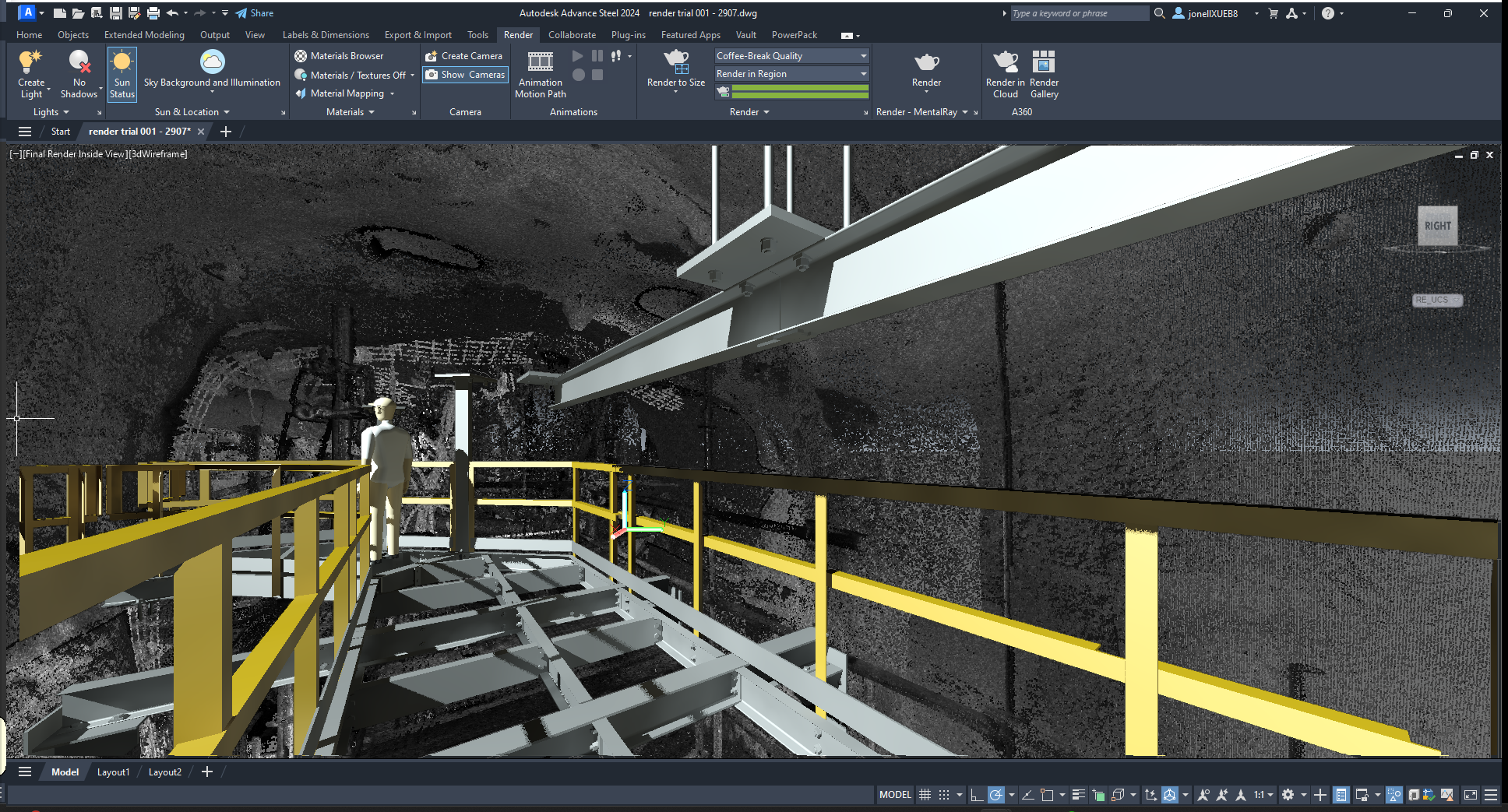

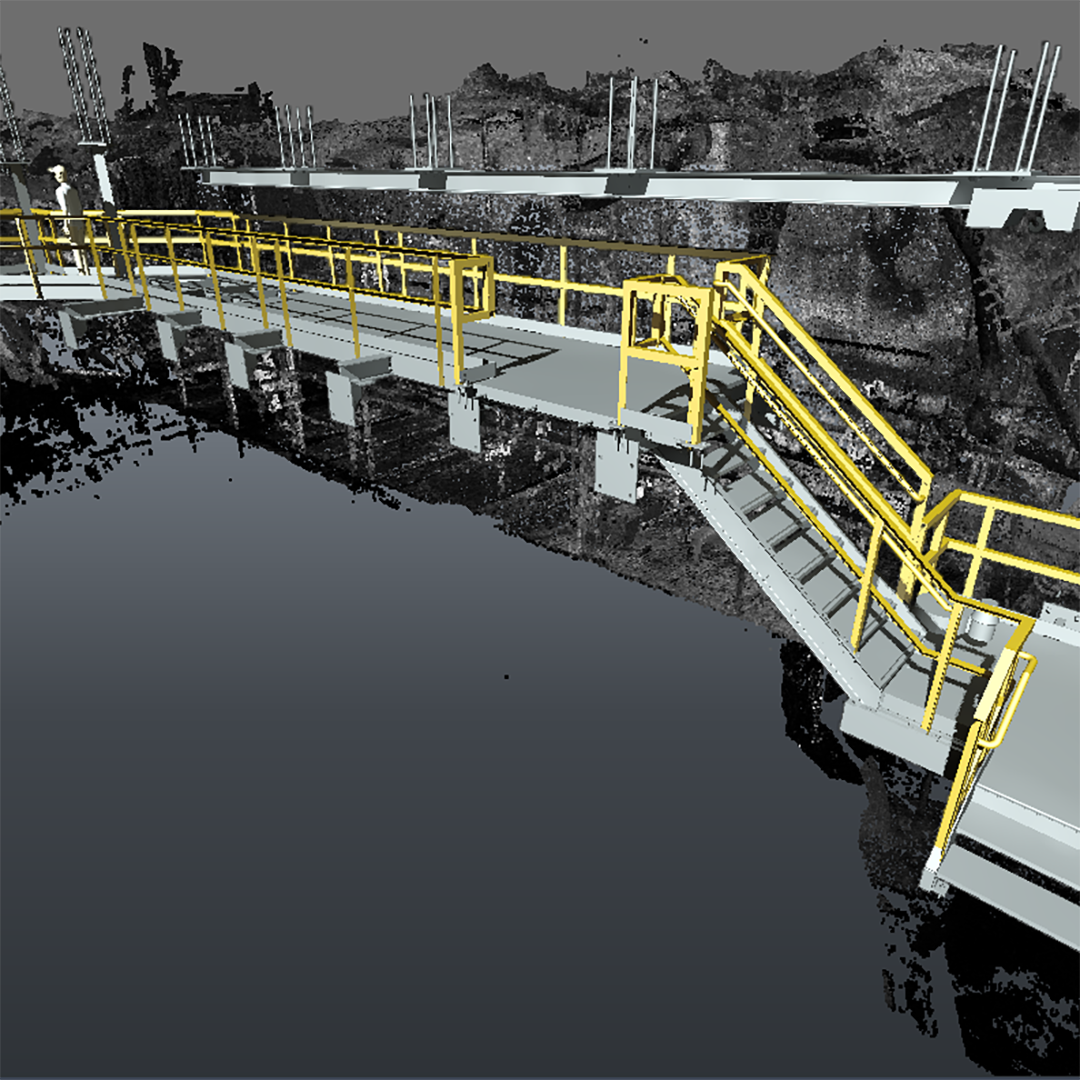

The 3D model was reviewed with the mine owner and the contractor to ensure that the design met the mine owner’s safety, construction, operational, maintenance, and ergonomic requirements.

Fabrication drawings were provided to the contractor from which the platform was built. The contractor installed the platform with relative ease which would have otherwise been labour intensive if the traditional “field verify” method was adopted.

Markets

Mining, Industrial

Status

Completed

An operating mine had a timber platform accessing an existing sump that required replacement. The replacement platform was to be of structural steel construction. The replacement steel had to fit to the existing complex drift profile.

In addition to the platform, a monorail to move pumps to and from the sump had to be included in the design.

A laser scan of the existing drift was performed. A 3D model using the resulting point cloud was created to ensure the platform fit in the existing drift and would easily install without interferences.

The 3D model was reviewed with the mine owner and the contractor to ensure that the design met the mine owner’s safety, construction, operational, maintenance, and ergonomic requirements.

Fabrication drawings were provided to the contractor from which the platform was built. The contractor installed the platform with relative ease which would have otherwise been labour intensive if the traditional “field verify” method was adopted.

SERVICES RENDERED: