The plant required a platform that would allow personnel to safely access and install spades to block process gases for maintenance activities. The area where the platform was to be installed was elevated and difficult to access. Additionally, the platform needed to provide means for personnel to safely access the platform, tie off, and manipulate the large spade plates.

Shield designed a platform that could be assembled on the ground and lifted into its intended position and secured in place.

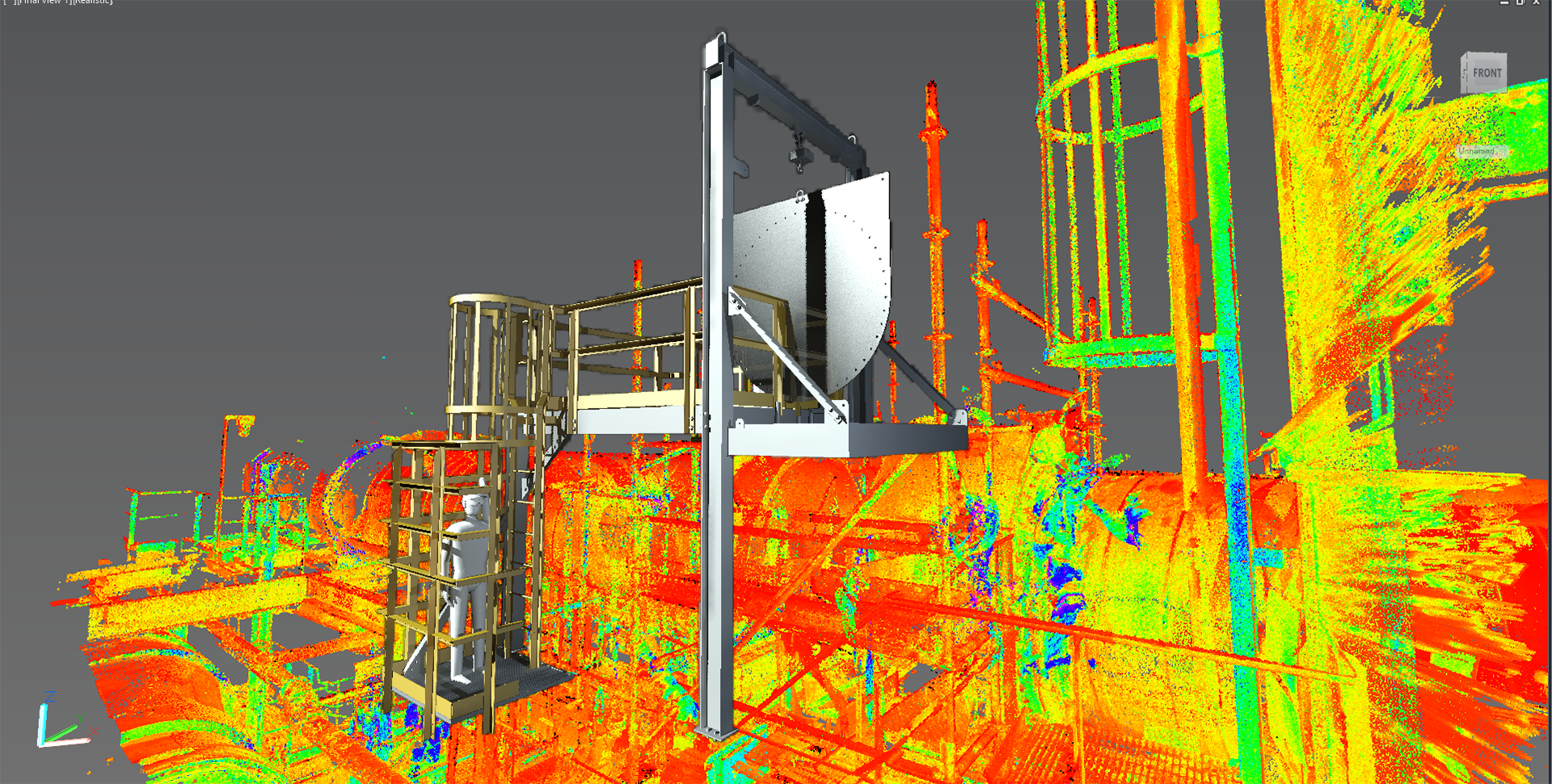

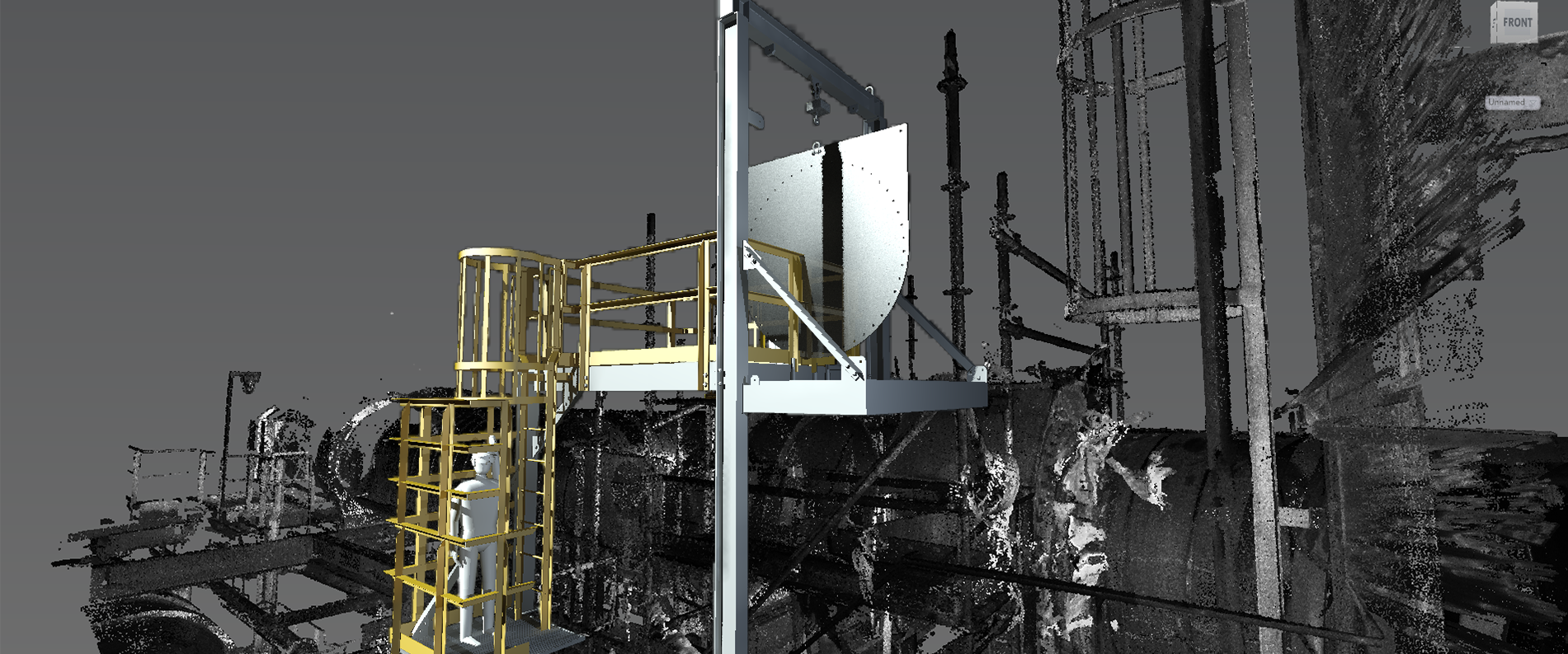

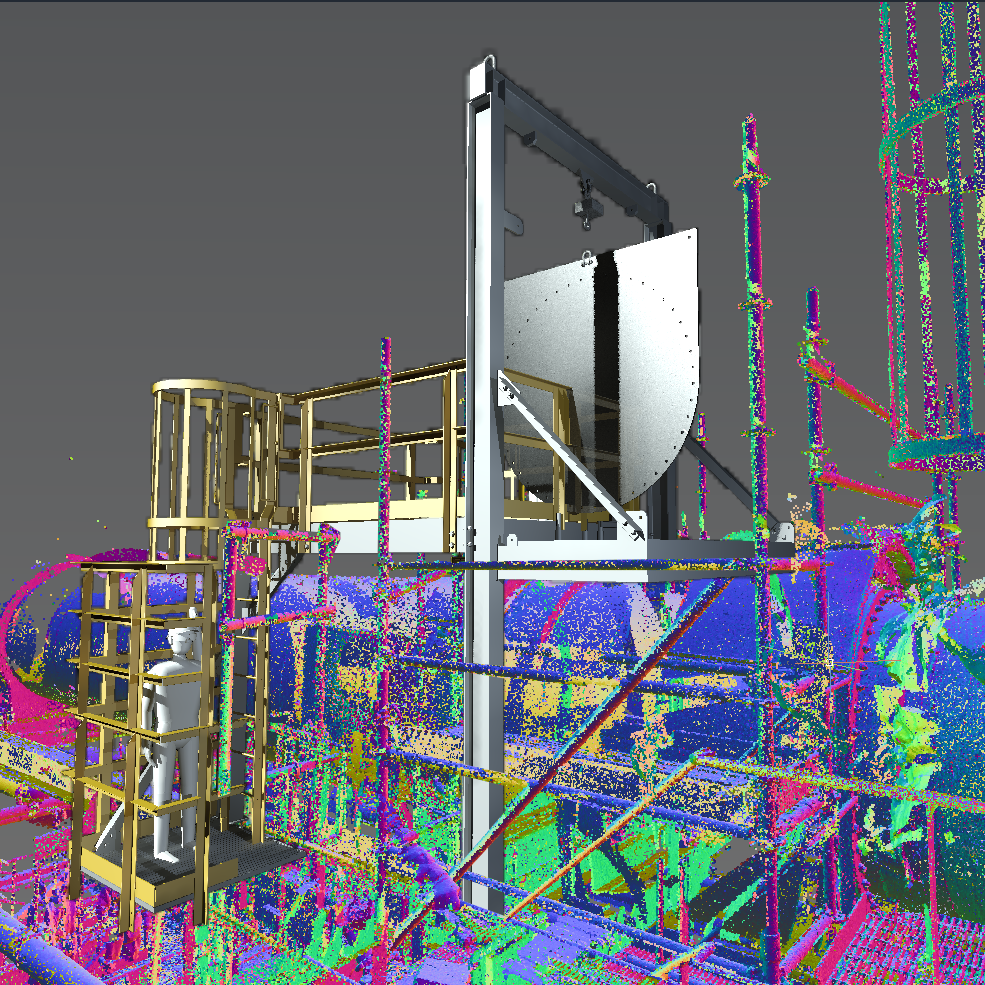

Shield laser scanned the area and created a 3D model of the platform in the scanned area. The design was reviewed with the project stakeholders to ensure that all aspects of the design met the clients needs, including installation & construction.

Shield provided fabrication drawings of the platform, allowing fabrication shops to directly build the provided the design. The client saved money by not having the fabricator re-draw the provided design and create their own set of fabrication drawings.

Once the platform was constructed, it was lifted into position and perfectly matched existing site conditions, eliminating the need for costly modifications in the field.

Markets

Mining Industrial

Status

Completed

The plant required a platform that would allow personnel to safely access and install spades to block process gases for maintenance activities. The area where the platform was to be installed was elevated and difficult to access. Additionally, the platform needed to provide means for personnel to safely access the platform, tie off, and manipulate the large spade plates.

Shield designed a platform that could be assembled on the ground and lifted into its intended position and secured in place.

Shield laser scanned the area and created a 3D model of the platform in the scanned area. The design was reviewed with the project stakeholders to ensure that all aspects of the design met the clients needs, including installation & construction.

Shield provided fabrication drawings of the platform, allowing fabrication shops to directly build the provided the design. The client saved money by not having the fabricator re-draw the provided design and create their own set of fabrication drawings.

Once the platform was constructed, it was lifted into position and perfectly matched existing site conditions, eliminating the need for costly modifications in the field.

SERVICES RENDERED: