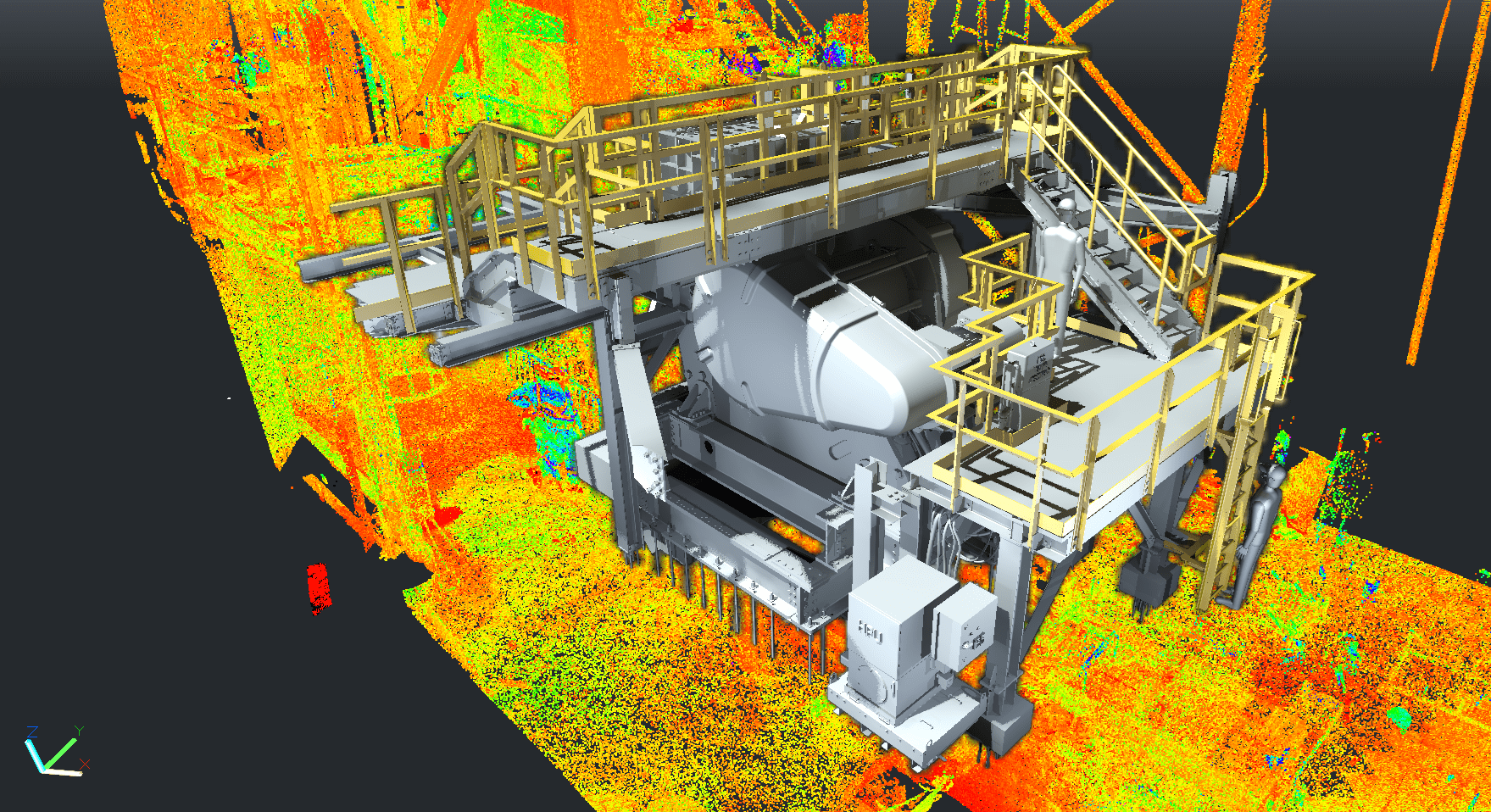

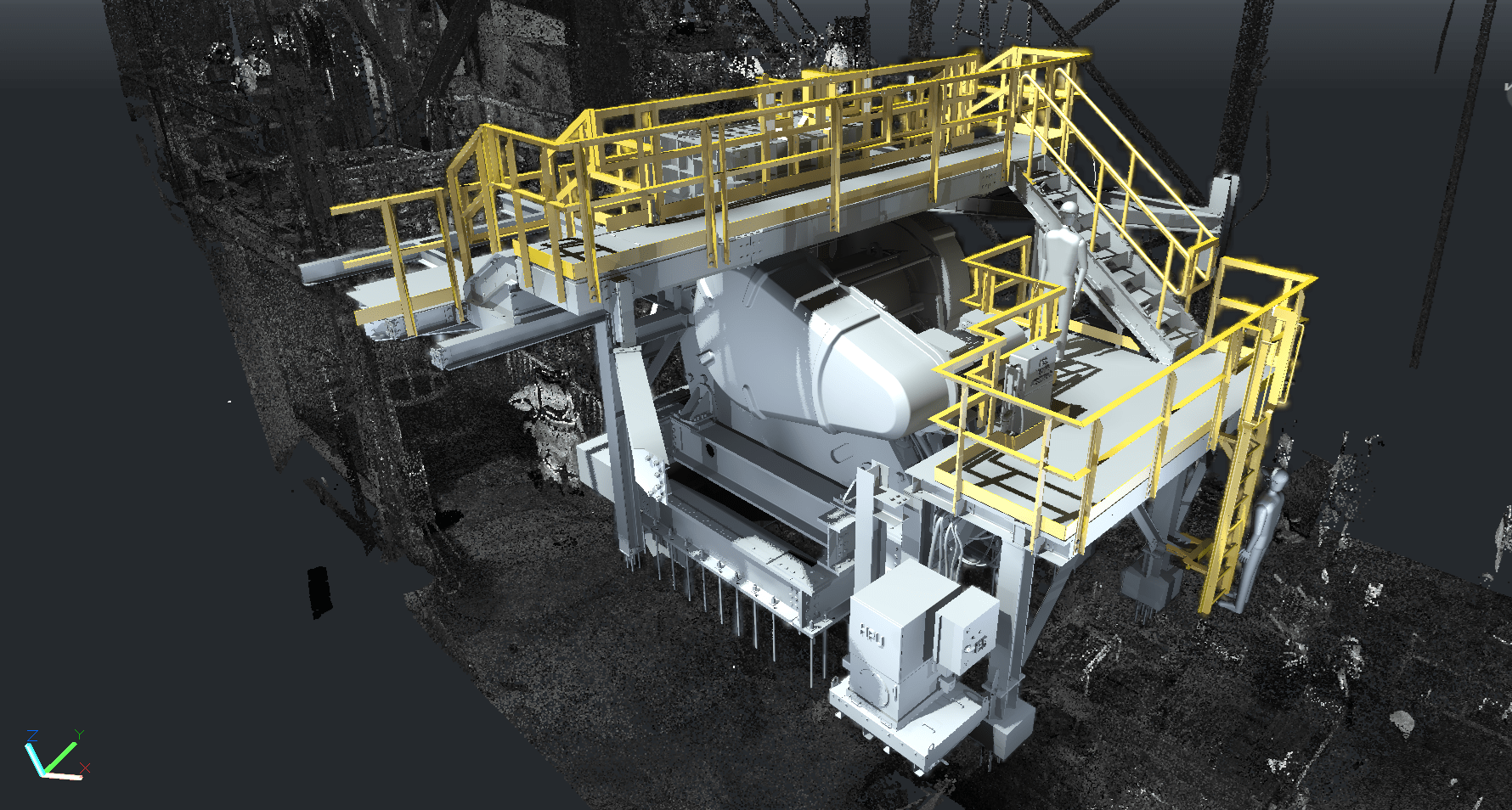

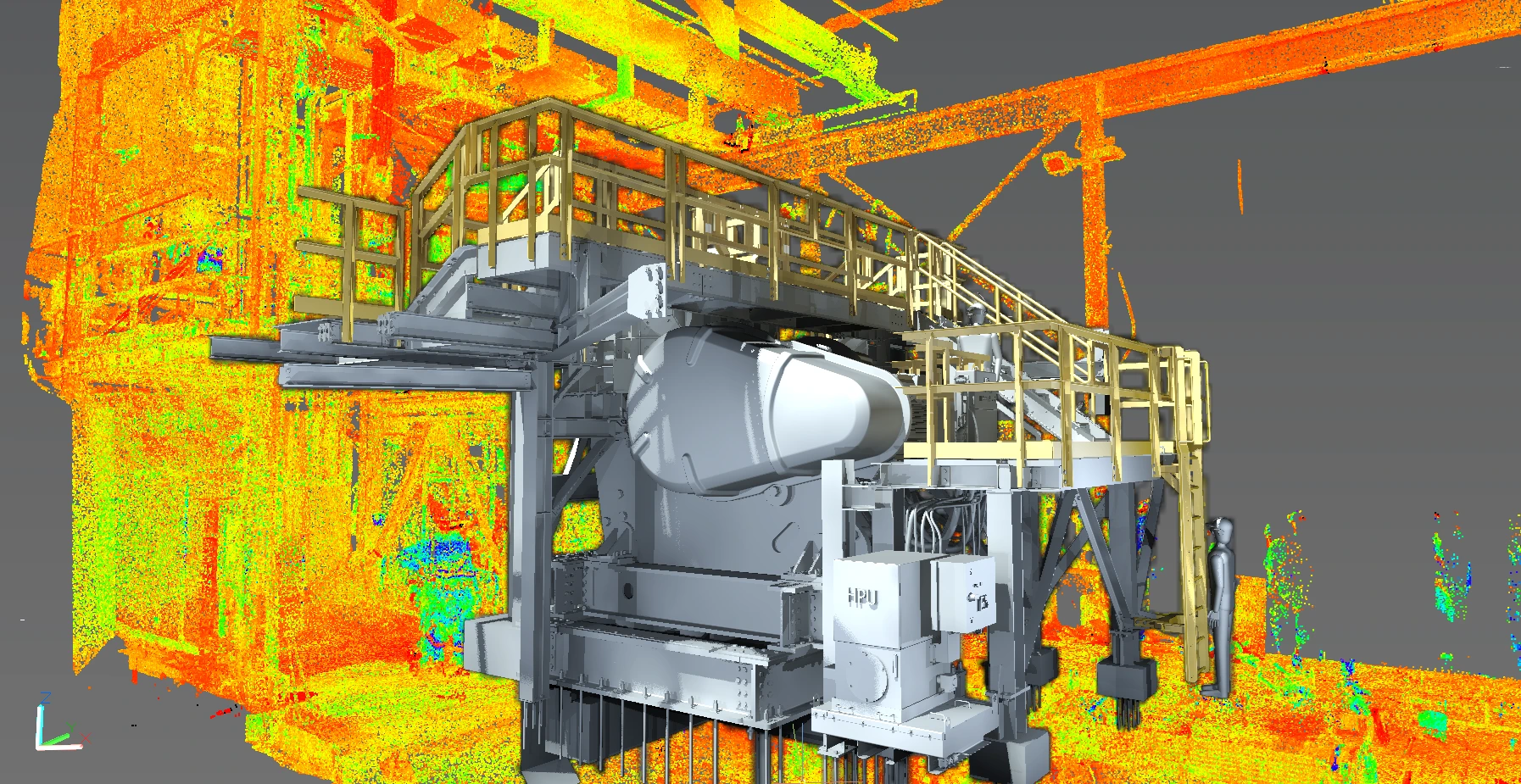

The client’s existing open jaw crusher rapidly developed defects that would limit its lifespan. As a result the client’s minesite had to replace the crusher in a short timeframe. The existing crusher was replaced with a modern, more compact open jaw crusher which required extensive modification to the steel work, material handling, electrical, and automation infrastructure to support it.

Shield was the only engineering consultant to accept the tight timeline and leveraged its technical abilities to rapidly re-design the material handling, structural steel, electrical and automation systems to provide its client with a functional replacement solution. Shield provided extensive support through the construction process, working closely with contractors and the mine owner to facilitate a condensed construction timeline, minimizing the mine’s downtime.

Markets

Mining

Status

Completed

The client’s existing open jaw crusher rapidly developed defects that would limit its lifespan. As a result the client’s minesite had to replace the crusher in a short timeframe. The existing crusher was replaced with a modern, more compact open jaw crusher which required extensive modification to the steel work, material handling, electrical, and automation infrastructure to support it.

Shield was the only engineering consultant to accept the tight timeline and leveraged its technical abilities to rapidly re-design the material handling, structural steel, electrical and automation systems to provide its client with a functional replacement solution. Shield provided extensive support through the construction process, working closely with contractors and the mine owner to facilitate a condensed construction timeline, minimizing the mine’s downtime.

SERVICES RENDERED: